CONTENTS

DETAIL DESIGN

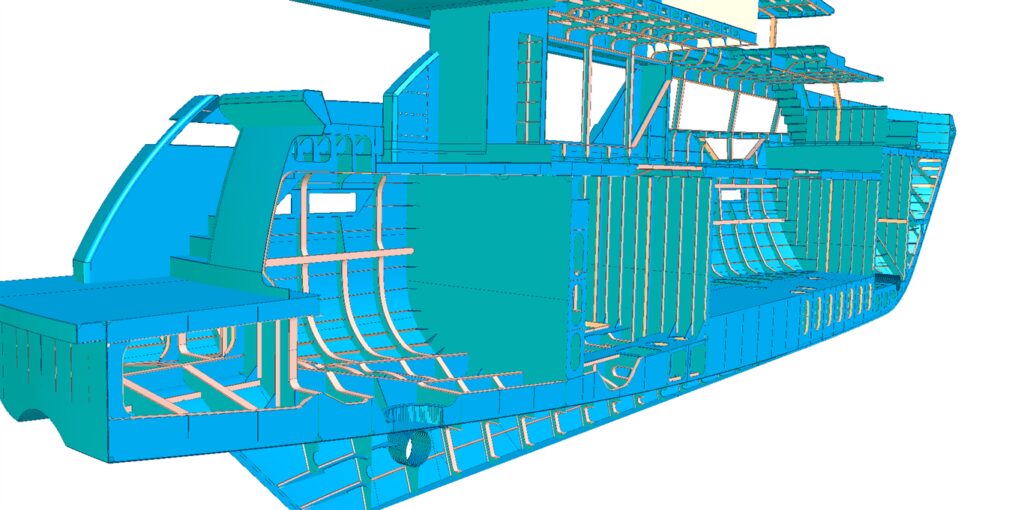

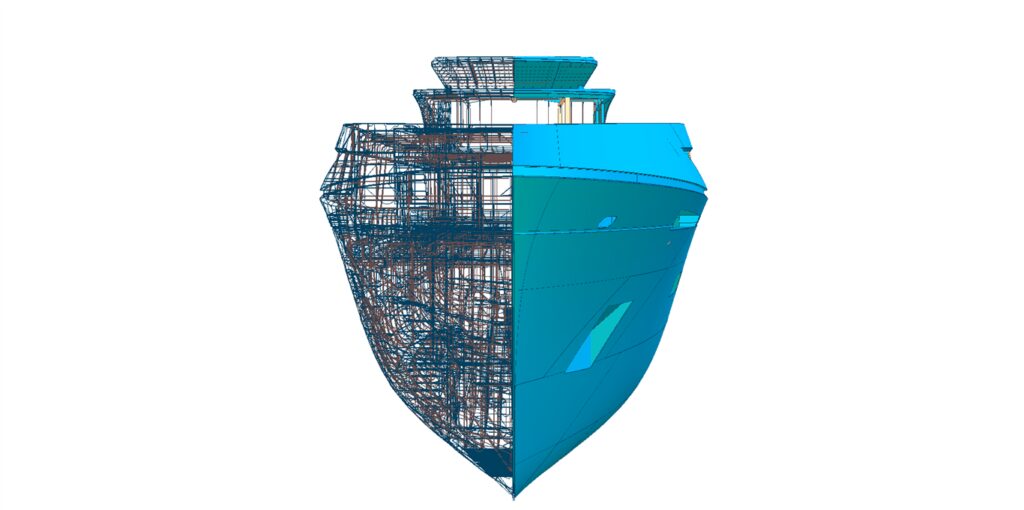

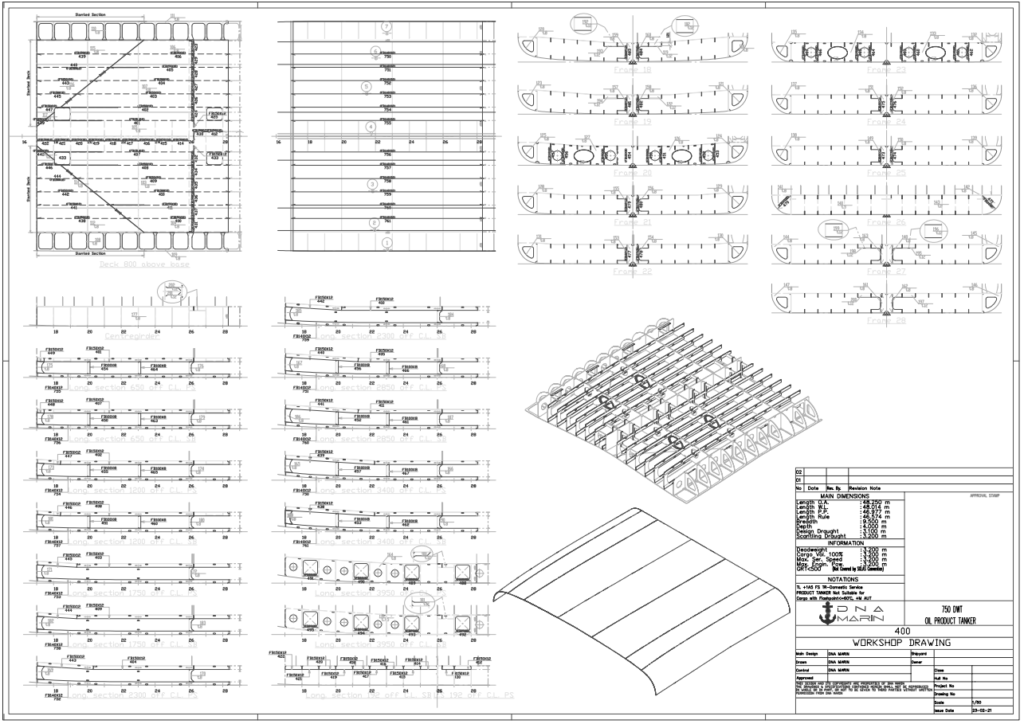

Detail engineering is the backbone of DNA Marin, all experience, knowledge and best practices are implemented. Top quality engineering in line with shipyard norms and engineering standards throughout the whole process is the most important point that enables shipyard to build vessel efficient and fastest way. Also in the detail design phase, we provide detailed 3D model visualisation to clients/shipyards to keep track on the progress which significantly increases the efficiency of the production process. Production information is generated automatically and 2D/3D assembly drawings are updated when changes are made in the 3D model.

With our sophisticated clash checks in the 3D model, we ensure error-free models and drawings for installation and production. It is always easier to solve these issues in the office while modelling than to deal with equipment and steel parts that have been delivered in the wrong sizes.

With the development of technology, we think that 3d models will soon go to classification societies for approval, and accordingly, we adapt our technology for new conditions.

Scope of Detail Design:

- Analysis of the approved drawings.

- Assessment of additional customer requirements.

- Analysis of the possibilities and typical construction technology of the selected shipyard.

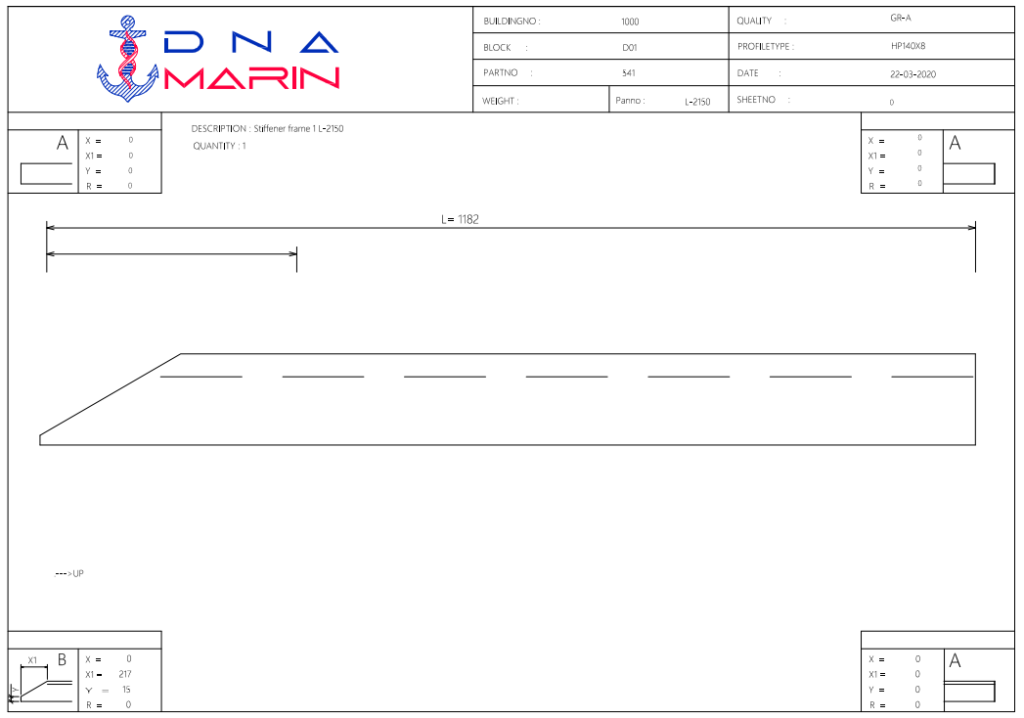

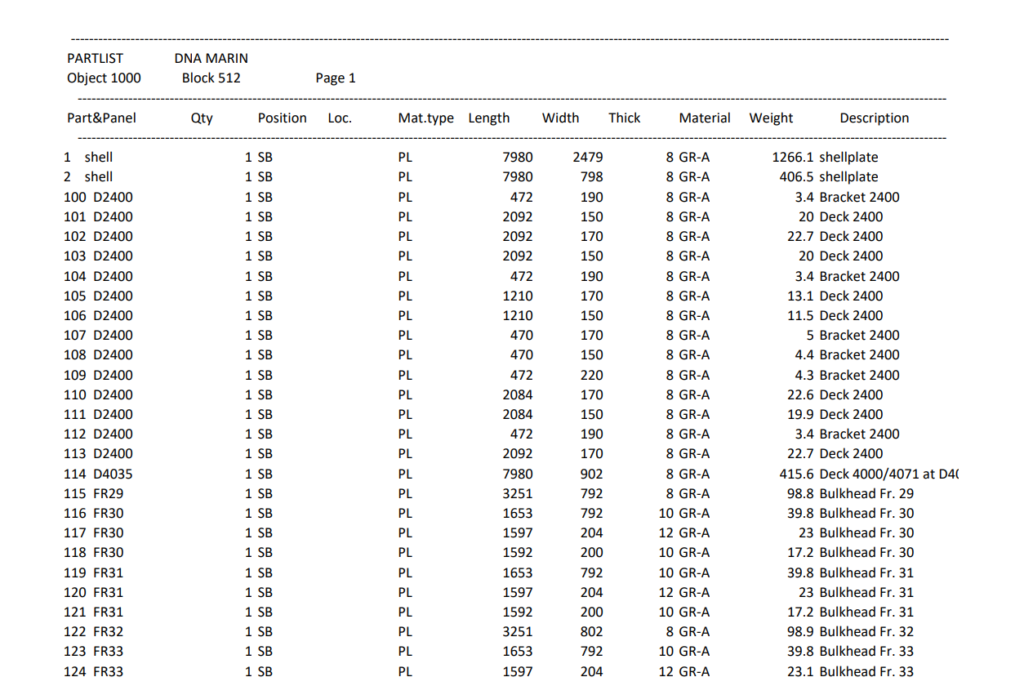

- Preparation of specifications, diagrams, plans and assembly drawings for the vessel.

- Development of scope and sequence of assembling/installation documentation.

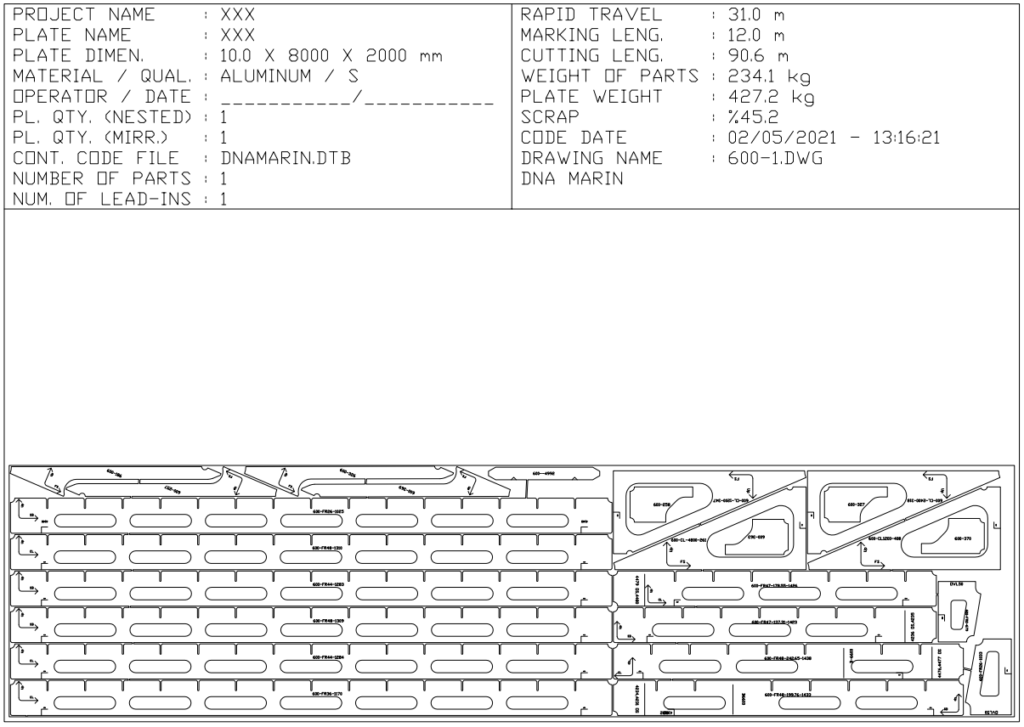

- Preparation of nesting and cutting programs.